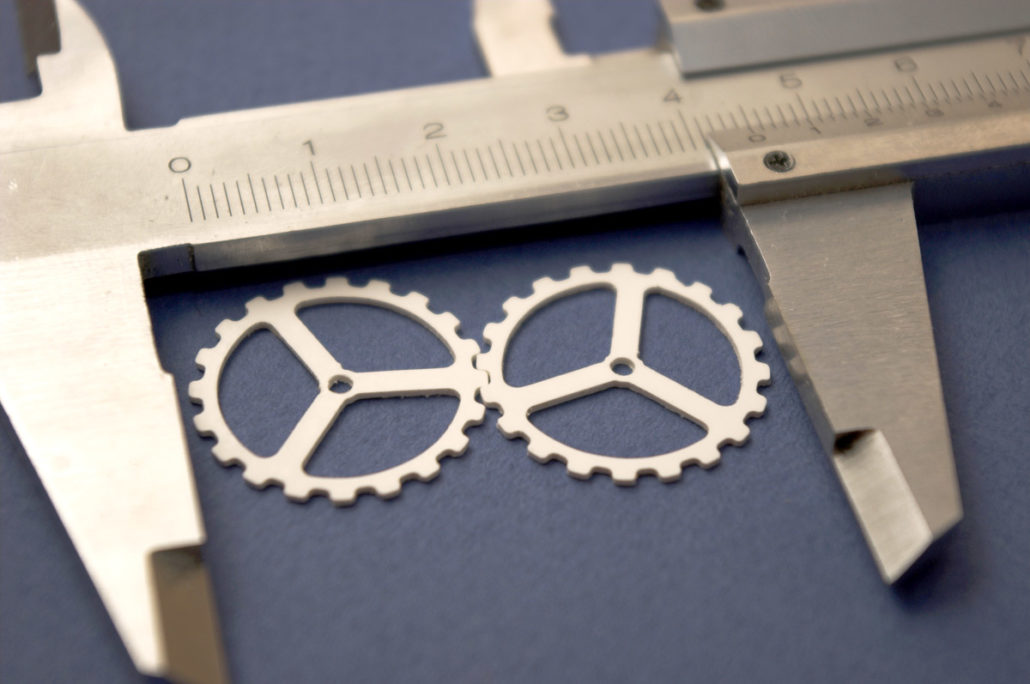

Routing/Milling plastic with high precision

Working with plastic on a CNC

All our machines are perfectly suited for routing/milling any kind of plastic such as acrylic, PVC, POM, and others. You can mill all varieties of plexiglass up to about 30 mm thickness, and with our special polishing cutters you get a nearly polished edge.

Many plastics have low melting points, so it is a good idea to use our mist cooling system.

Common applications are model building, advertising, signs, and prototyping.

Common plastic types, some seen In the above examples, are POM, plexiglass, polycarbonate, Depron, Trespa HPL laminate, PVC, rigid PVC, PTFE, PE, PS, PA, and PEEK.

Some things to keep in mind when working with plastics:

- Make sure to clamp the material without putting stress on it. This prevents the material from deforming upon release.

- Softer plastics are often more difficult than harder types. Use extremely sharp cutting tools. And make sure to use air or preferably a mist cooling system to remove chips during milling. That will give you better edge surface quality.

- Keep the spindle RPMs low. This will ensure that the material doesn't heat up too much.

Need to see some action? go ahead...

Not had enough yet? No problem.

Head on over to the Tube and browse there instead...