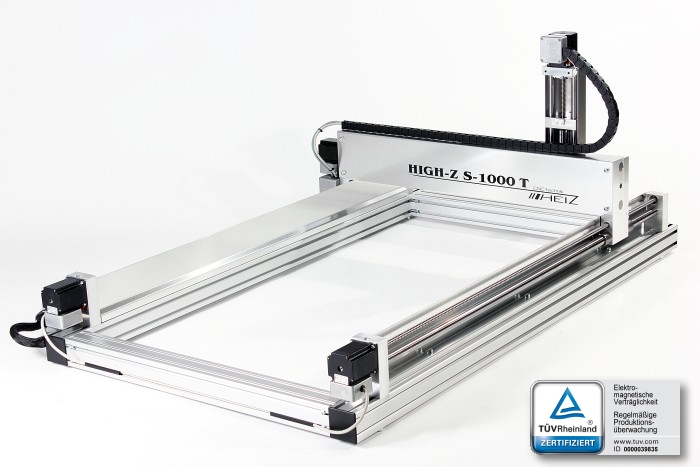

High-Z Turbo - a faster cNC machine with even higher precision

Router, mill, engrave, cut and much more on these versatile bestselling CNC machines

HIGH Z TURBO

Designed for industrial use

Affordable enough for hobby

Ball screws

Open frame in X and Z directions

Premium professional quality

Huge range of accessories

Free support

Unbeatable price

Made in Germany

Need something cheaper or more heavy duty?

Check out High-Z Standard or T-Rex

The multi-purpose High-Z CNC Machine – Turbo series with ball screws for ultimate precision at this price

Bestselling CNC machine for professional use and serious enthusiasts.

The High-Z Turbo series is regarded all over the world as an affordable CNC machine for professional use. We have customers running them seven days a week in production or testing environments. And they are also loved by hobbyists for their precision, reliability, and ease of use at very reasonable price points.

The Turbo machines are based on the Standard model. They were developed to guarantee more accuracy (repeat accuracy of 0,01 mm) and higher speed. As an extra benefit, they also have better longevity. When you are looking for speed, precision, easy maintenance, and unsurpassed longevity, you have finally struck gold. The High-Z Turbo is what you need.

Just like the Standard models, our Turbo CNC machines have emergency stop buttons both on the machine itself and on the controller.

If you are new to CNC – don’t worry. Our machines are extremely easy to use, and we offer free support if you have any questions at all.

We will recommend the best software for your needs, unless you already have CAD/CAM solutions that you prefer. And if you have a special CNC application that you need help with, please get in touch so we can help you find the best possible solution.

Five models available: 400T, 720T, 1000T, 1400T, 1400T/105

High-Z 400 Turbo

High-Z 1400 Turbo

High-Z 720 Turbo

High-Z 1400/105 Turbo

High-Z 1000 Turbo

Features

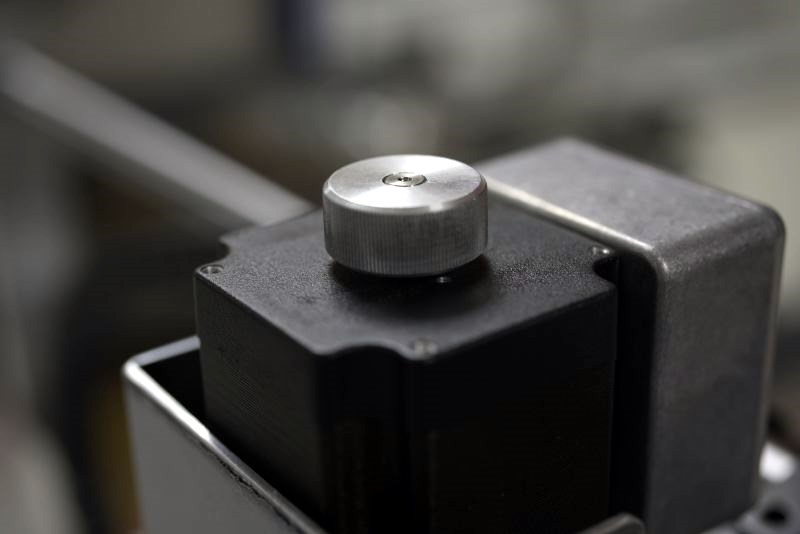

Drive: 4 brushless stepping motors by Nanotec with 4,2 A each

Ground and 61 hrc surface hardened guides: X/Y axes, 22/22 mm or 22/30 mm / Z axis, 16mm

HiWin profiled linear guides as standard on the 1400T and 1400T/105

Ø 10/12.7 mm premium ball screws and ball screw nuts

Ball bearings at both sides of lead screws on X and Y axis

2 X-axis motors, one on each side for an open frame design with maximum versatility

Unobstructed material loading in the X direction

Working speed around 8000 mm/min max.

Traverse speed of rapid feed: max. 12000 mm/min

Technical resolution : 0,005 mm/0.00635 (1/10 Step)

Max backlash: 15µm (0,015 mm)

Repeatable accuracy: 10µm (0,01 mm)

Reference- and limit switches on all axes

Emergency stop button on both machine and controller

Energy chain for clean cabling

Standard spindle/router mount: Ø 43mm

Standard control software: WIN PCNC USB with other options available such as KineticNC

5-channel micro step controller Zero3 with 4 x 3,5 A output for steppers

Huge range of accessories and extra options available

FREE support

| Technical data High-Z CNC Turbo with ballscrews | S400 T | S720 T | S1000 T | S1400 T | S1400 T/105 |

|---|---|---|---|---|---|

| Article Number | 100110 | 100120 | 100130 | 100140 | 100160 |

| X Axis Travel | 400 mm | 720 mm | 1000 mm | 1400 mm | 1400 mm |

| Y Axis Travel | 300 mm | 420 mm | 600 mm | 800 mm | 1050 mm |

| Z Axis Travel | 110 mm | 110 mm | 110 mm | 110 mm | 110 mm |

| Max gantry clearance | 107 mm | 107 mm | 107 mm | 109 mm | 109 mm |

How about some general information about CNC routers?

CNC machines do the work of many hands - automatically. Sometimes it may even look like magic. CNC machines are common tools in many production environments today. And the most common uses are in the wood, plastic, and metal product manufacturing industries. But the number of special applications are ever increasing. And since they have been around for a while, and the technology has matured, they are now accessible even to small businesses and hobbyists.

What is a CNC Router?

CNC is an abbreviation that stands for “computerized numerical control.” You start with a machine frame and attach a tool, say a router with a router bit. The frame is made so that it can move the router up and down, side to side, and back and forth. Connect this setup to a controller and a PC, and you have a router that can be controlled numerically via a computer.

Sounds complicated? Well, it may be easier than you think, and we have people from all walks of life who run our machines without any experience. There are great tutorial online, we can send custom videos to you, and we can even log on to your computer to show you the ropes.

And the software has come a long way to become extremely user friendly.

So how do I use a CNC machine?

The work flow is quite simple.

Draw or model an item in a CAD program such as the extremely user friendly VCarve Pro.

Then enter a few parameters in the CAM part of the software. For example, you enter what tool you are using, how fast you want to go, and what type of cutting you want to do. Then hit the calculate button. And out comes a code called G-Code.

This code is then read by the controller software, for instance WinPCNC USB or KineticNC

Position the cutting tool where you want it to begin, and press start... It can really be that easy.

But of course, the results will vary depending on the thought you put into your design, the quality of your material, and the quality of the machine you are using. With a machine from us you know the latter is taken care of.

What materials can you work with on a CNC machine?

High-Z machines are optimized for maximum performance in the widest range of materials at the best possible price. They have the widest application range on the market and can process most materials including the following:

Brass

Aluminum

Titanium

Silver and gold

Steel

All wood

Plastics

Acrylic glass

Glass

Stone such as marble and granite

And much more!

Keep in mind that for the harder materials we offer a milling kit which is an additional guide rail across the gantry. This increases the rigidity of the Z axis. We include it as standard for all routing and milling applications.

And when milling metals, stone, and some plastics you want to use a minimal lubrication system, or a spay mist cooling unit. It prevents overheating and premature wear of the tool by clearing away chips and debris that would otherwise clog the flutes of the cutting tool.

Need to see some action? go ahead...

Not had enough yet? No problem.

Head on over to the Tube and browse there instead...